Why the Engineer Should Specify Shop Made Fittings

Shop Made Fittings are recognized and specified worldwide by major engineering firms. The U.S. Army Corps of Engineers also selected Shop Made Fittings in the July 1995 revision of CEGS Section 03250. Shop Made Fittings are specified because they work. Edge welding waterstop seriously compromises the integrity of any project. Even the limited concrete movement during the coefficient of expansion and contraction can be too much for edge welded waterstop. The edge welded waterstop lacks the proper tensile strength and does not maintain the characteristics of the parent material (bulb or rib continuity). Consequently, the waterstop often tears at the most critical junction: the change of direction since all waterstops are designed to act as a continuous, fluid-tight diaphragm which fluids (generally water) traverse, the structure that uses edge welded waterstop will naturally leak, as fluids migrate to any tears in the weld and pass through to the other side of the joint.Structures that use Shop Made Fittings will significantly reduce these waterstop failures. The tensile strength of the weld will be at least 80% of the parent material, and the bulb and rib continuity is maintained across the weld. In other words, the waterstop will perform as intended and last the life of the structure.

CAD Drawings

J P Specialties has an extensive library of CAD drawings that illustrate the many uses of various Shop Made Fittings and explain waterstop's role in creating a fluid-tight structure.Why the Contractor Should Use Shop Made Fittings

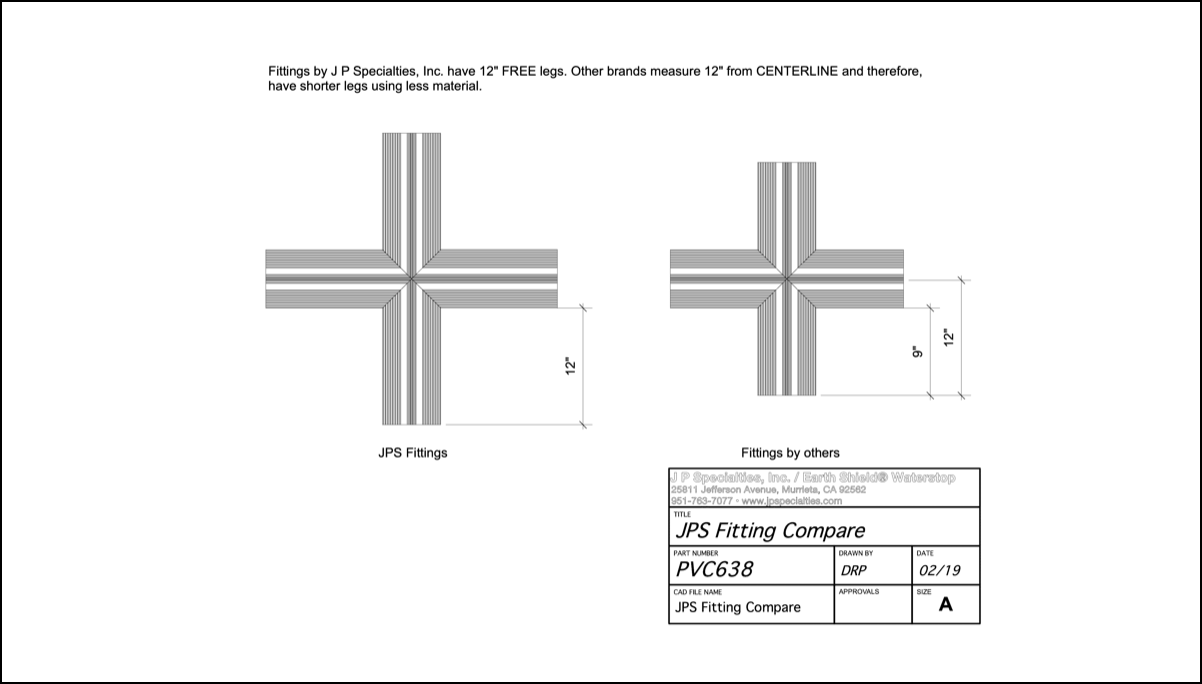

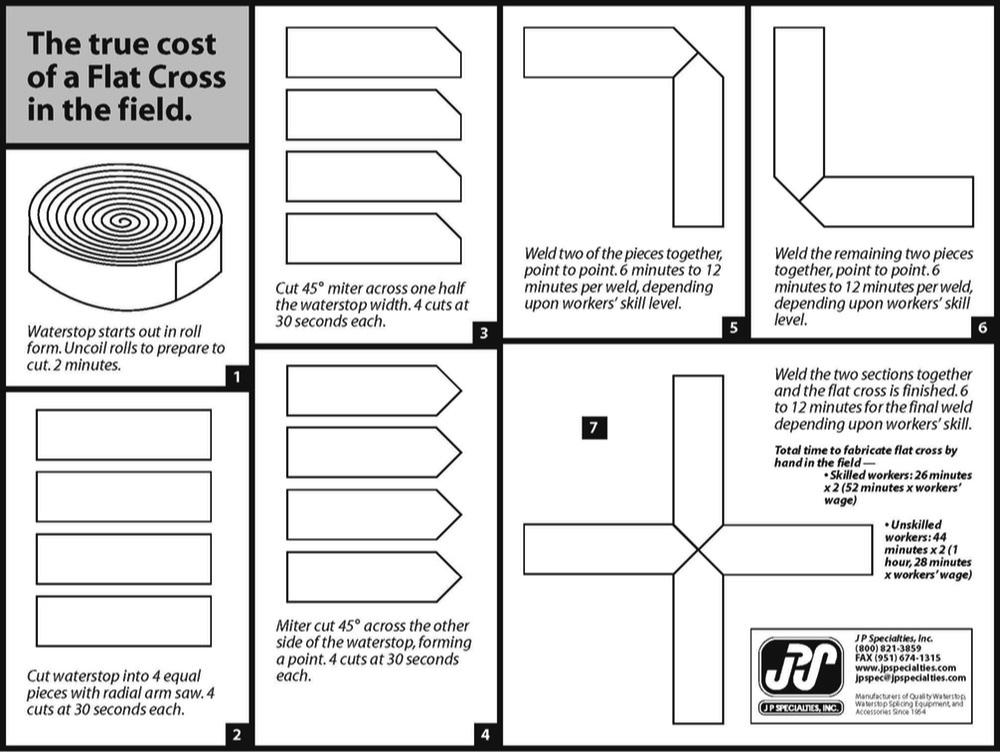

J P Specialties certified welding crew can efficiently manufacture large quantities of top-quality Shop Made Fittings with speed on our exclusive XLT-2000 Waterstop Splicing Tables. Therefore, we pass the savings on to the contractor. Besides saving money, the contractor who uses Shop Made Fittings will save time. A standard flat cross has twelve cuts and three welds. Shop Made Fittings eliminate all of the cuts and welds.

2.4 WATERSTOPS - Intersection and change of direction waterstops shall be shop fabricated.

U.S. Army Corps of Engineers CEGS-03250

What are Shop Made Fitting Modules?

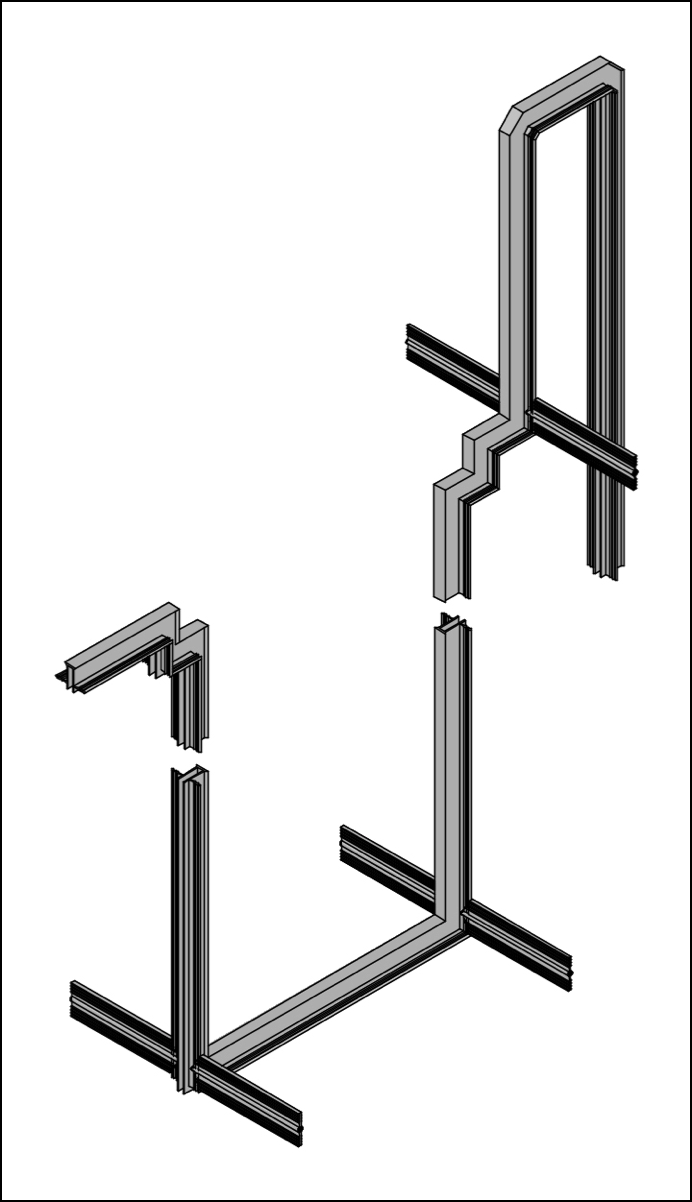

Modules are custom Shop Made Fittings delivered to the job site as a complete unit rather than a collection of parts. For example, a box culvert with a longitudinal joint would typically require four vertical ells and two flat crosses. Even with Shop Made Fittings, this would be sixteen butt welds (straight edge to straight edge) for the contractor in the field. With proper dimensions from building plans, J P Specialties will manufacture entire box culvert modules. In the above box culvert example, only four butt welds remain to be done in the field using modules.Modules work best when the engineer specifies them during the design phase of the project. However, they are also effective during the construction phase with close collaboration between J P Specialties and the contractor. J P Specialties can interpret project plans during any stage of construction and render how Shop Made Fittings or modules will improve the quality of your structure and save you money.

How Much Do Shop Made Fittings Cost?

Shop Made Fittings are supplied at cost savings to the contractor on most jobs than the time and labor necessary to fabricate the Waterstop in the field. Providing Shop Made Fittings will be more cost-effective and will ensure a timely installation, thus saving costly delays. Also, our Shop Made Fittings will enhance your ability to meet stringent hydraulic tests required by engineers.